Understanding the Live Axle of a Truck and Its Maintenance Requirements

The live axle is a critical component in most trucks, playing a vital role in transferring power from the engine to the wheels while supporting the vehicle’s weight. It ensures stability, traction, and load-bearing capacity, particularly for heavy-duty trucks. To guarantee safety on the road, proper maintenance of the live axle is essential. Neglecting this important component can lead to vehicle breakdowns and accidents, putting lives and goods at risk.

What is a Live Axle?

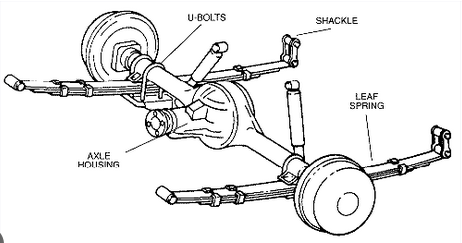

A live axle is a type of axle that transmits power directly to the wheels. Unlike a dead axle, which only supports weight, a live axle actively drives the wheels, making it integral to a truck’s propulsion and load management. It consists of:

- Axle Housing: Encloses and protects the differential and other components.

- Differential: Allows the wheels to rotate at different speeds, crucial for turning.

- Drive Shafts: Transfer power from the differential to the wheels.

- Bearings and Seals: Reduce friction and prevent lubricant leaks.

Importance of Live Axle Maintenance

- Ensures Road Safety:

- A malfunctioning live axle can lead to loss of control, especially under heavy loads or at high speeds.

- Poor maintenance can cause axle failure, resulting in accidents.

2. Prolongs Vehicle Life:

- Proper care reduces wear and tear, extending the lifespan of the axle and related components.

3. Enhances Performance:

- A well-maintained live axle ensures smooth power transmission, better fuel efficiency, and improved handling.

Maintenance Requirements for the Live Axle

- Regular Inspection:

- Check the axle housing for cracks, dents, or other damage.

- Inspect drive shafts for signs of wear or misalignment.

2. Lubrication:

- Ensure the differential and bearings are adequately lubricated to reduce friction and heat.

- Replace the axle oil at intervals recommended by the manufacturer, typically every 20,000 to 50,000 miles.

3. Seal and Bearing Maintenance:

- Inspect seals regularly to prevent oil leaks.

- Replace worn-out or damaged bearings to avoid excessive friction and overheating.

4. Check for Noise and Vibrations:

- Unusual noises or vibrations while driving may indicate issues with the differential or drive shafts. Address these promptly.

5. Alignment Checks:

- Ensure the axle is properly aligned to prevent uneven tire wear and maintain vehicle stability.

6. Load Management:

- Avoid overloading the truck, as this puts excessive stress on the axle and other components.

Consequences of Neglecting Live Axle Maintenance

- Increased Accident Risk: A damaged live axle can cause sudden loss of control, especially in adverse weather conditions or on uneven roads.

- Costly Repairs: Ignoring minor issues can lead to major failures, requiring expensive repairs or replacements.

- Downtime: A truck with a faulty live axle may be out of service for extended periods, affecting delivery schedules and profitability.

Conclusion

The live axle is a vital part of a truck’s drivetrain and load-support system. Regular maintenance, including inspections, lubrication, and prompt repairs, is essential to ensure road safety and optimal vehicle performance. Truck owners and drivers must prioritize live axle care as part of their overall vehicle maintenance routine. By doing so, they not only protect their investment but also contribute to safer roads for everyone.

Comments

Post a Comment